Products

Industrial Division

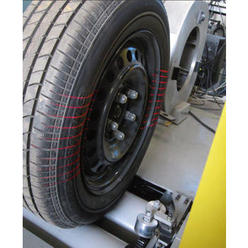

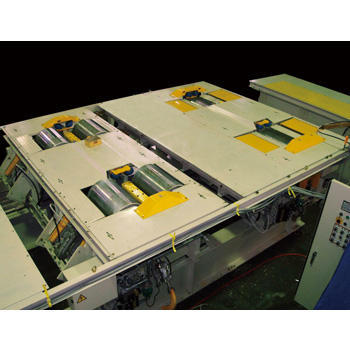

• This tester measures Tire mounting angles (toe-in and camber angles) for Assembled vehicles to make the necessary adjustments.

• With our proprietary tire clamp facing mechanism, the tester provides high reliability.

• The device uses a non-contact 3D laser sensor for high-precision measurements.

• Equipped with a color CCD camera, this tester recognizes light tones based on R, G, and B values to provide analyses comparable to the human eye.

• The tester reliably analyzes light distribution patterns of VOL and VOR and light from HID and LED lamps.

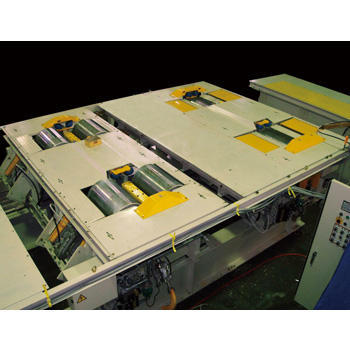

• This device runs on rollers that have the same inertial weight as the target vehicle weight to check running conditions and the accuracy of the speedometer.

Standard specs [Click to open]

| Axle weight | 1,500 kg (Custom) |

|---|---|

| Wheelbase | 2400 - 3000 mm (Custom) |

| Tread | 1,300 mm - 1,600 mm (Custom) |

| Roller Size | L600 mm (Front/Rear) Front370 mm, Rear740 mm (Custom) |

| 3rd roller | Front side of front roller 2 nos. (φ80 × L500 mm) Rear side of front roller 2 nos. (φ80 × L500 mm) Rear side of rear roller 2 nos. (φ80 × L500 mm) |

| Maximum measuring speed | 140 km/h (Custom) |

| Angle sensor | Rotary encoder |

| F/R connection device | Electro magnetic clutch and V-belt |

| Inertia equivalent weight | About 400 kg (Custom) |

| Power supply voltage | 380 VAC±10%, 3P, 50±3Hz 10 kVA (Custom) |

| Required supply air pressure | 0.5 MPa (5 kg/cm2) |

| Measurement item | Speed test |

| Speed pattern test | |

| 4WD check | |

| Equipment composition : | Main machine |

| Control panel | |

| Operation panel | |

| Drivers display (Overhead) | |

| Drivers operation panel (Pull switch) | |

| Vehicle select panel (Pull switch) | |

| Emergency box in pit | |

| Option : | Calibrator |

| Exhaust gas discharge equipment | |

| Camera system | |

| Electricity generation system | |

| Auto light check | |

| OBD check | |

| Inertia equivalent weight control | |

| Barcode reader | |

| Online system |

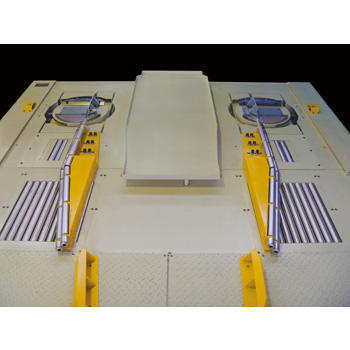

• This device measures the braking force of Assembled vehicles.

• According to the customer request, the device can be configured to test vehicle-braking systems such as ABS.

Standard specs [Click to open]

| Axle weight | 1,500 kg (Custom) |

|---|---|

| Wheelbase | 2400 - 3000 mm (Custom) |

| Tread | 1,300 mm - 1,600 mm (Custom) |

| Roller Size | 185 mm (Custom) |

| Braking force detector | Load cell |

| Maximum Braking Force | 4000 N (Custom) |

| Braking force test speed | 0.2 - 4 km/h (Custom) |

| Braking force detector | Load cell |

| Power supply voltage | 380 VAC±10%, 3P, 50±3Hz 30 kVA (Custom) |

| Required supply air pressure | 0.5 Mpa (5 kg/cm2) |

| Measurement items | Brake test |

| parking brake test | |

| Drag test | |

| Equipment composition | Main machine |

| Control panel | |

| Operation panel | |

| Drivers display (Overhead) | |

| Drivers operation panel (Pull switch) | |

| Vehicle select panel (Pull switch) | |

| Emergency box in pit | |

| Option | Calibrator |

| ABS check | |

| Traction control check | |

| Vehicle stability control check | |

| Foot power check | |

| Pull power check | |

| Axle weight | |

| Barcode reader | |

| Online system |

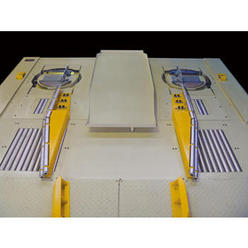

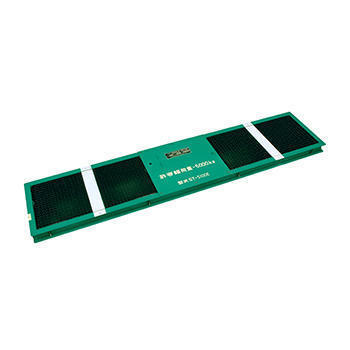

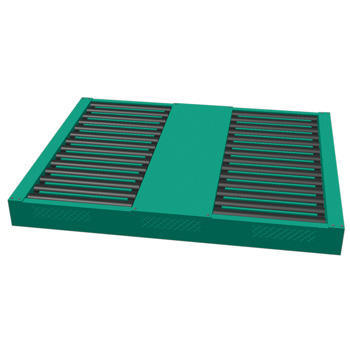

• Side Slip Tester is designed to measure the amount of Side Slip and Axle Slip.

• The tester is based on a mechanism that allows for easy maintenance.

Standard specs [Click to open]

| Axle weight | 1,500 kg (Custom) |

|---|---|

| Wheelbase | 2400 - 3000 mm (Custom) |

| Tread | 1,300 mm - 1,600 mm (Custom) |

| Board size | W600 × L1,000 mm (Custom) |

| Measurement amount detector | Potentiometer |

| Board lock device | Pin |

| Vehicle detector | Photoelectric switch |

| The range of measurement | ±15 mm |

| Power supply voltage | 380 VAC±10%, 3P, 50±3 Hz 30 kVA (Custom) |

| Measurement item | Side slip test |

| Equipment composition | Main machine |

| Control panel | |

| Operation panel | |

| Drivers display (Overhead) | |

| Drivers operation panel (Pull switch) | |

| Vehicle select panel (Pull switch) | |

| Option | Calibrator |

| Barcode reader | |

| Online system |

• A comprehensive inspection line developed for light cars.

After Market Division

An evolving ANZEN's twin power lift

・Enhanced the safety because this is the lift for mechanics.

Ample safety deices such as sudden fall prevention device.

・The various attachment and holders make it easy to set.

・The "floor flat" mechanism make it easy for the vehicle to enter or exit.

An evolving total vehicle-inspection system

• The ALM2012 provides higher quality of vehicle inspection by controlling all inspection operations systematically.

• The system provides streamlined operations with excellent functionality and usability achieved through the unrelenting efforts of our personnel.

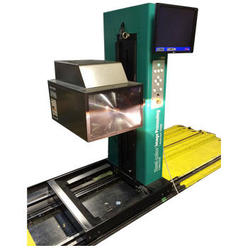

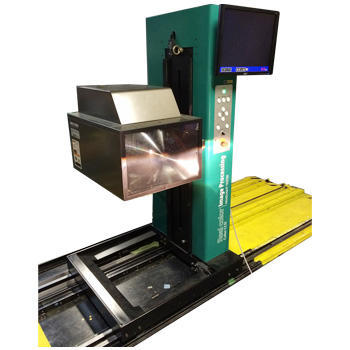

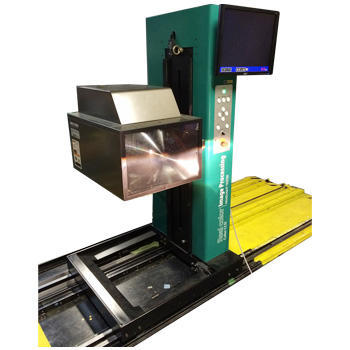

Advanced fully automatic headlight tester equipped with a color CCD camera that recognizes color tones.

• With the advantage of color cameras, the HLI-2015 recognizes lamp tones from the combinations of R, G, and B values to provide analyses comparable to the human eye.

• The HLI-2015 accurately recognizes light distribution and tones from sources ranging from halogen lamps, which emit reddish light, to HID/LED lamps, which emit bluish light. The tester also reliably recognizes light from new types of light sources.

Advanced headlight tester equipped with a color CCD camera that recognizes color tones with screen.

• With the advantage of color cameras, the HLI-215 recognizes lamp tones from combinations of R, G, and B values to provide analyses comparable to the human eye. The light receiving section and monitor move up and down automatically.

With enhanced functionality and practicality, the HL-211S delivers high-cost performance.

• The tester recognizes light coming from the opposite direction in two different ways: screen- and laser-based! It quickly and reliably recognizes light from any lamp facing the tester.

• The HL-211S measures light from fog lamps down to 25 cm.

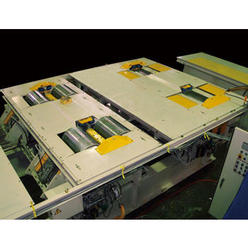

Integrated testers act as a sideslip, brake, and speedometer tester.

• The series offers five models that combine a brake, a speedometer, and a sideslip tester. Choose the desired model according to the points of importance, such as target vehicles and quietness.

• The testers can be used for a variety of vehicles with axle weights of up to 3.6 tons.

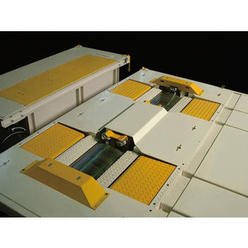

A flat BS tester allows you to conduct tests without paying attention to your foot!

• This tester can be installed in an existing pit, which is recommended as a replacement for existing testers.

• The BS-212 can be used for a variety of vehicles with axle weights of up to 3.6 tons.

• With a low-profile design and a main unit height of 250 mm, the tester can be installed even in a multistoried workshop.

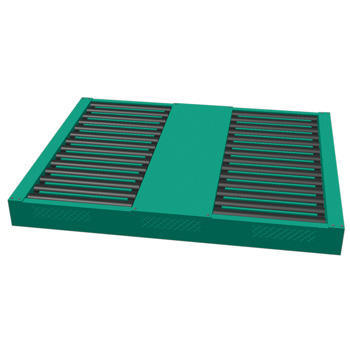

Flat, compact testers provide the ideal environment for vehicle inspections.

• The testers work with a variety of vehicles ranging from light cars to large buses and trucks.

• With a full-flat body, the testers do not disfigure the workshop.

• The roller comes in two types. According to the application, choose the grooved roller (for the BS-2022) or the grooved noiseless roller (for the BS-2022S).

The ST-211H covers a wide range of vehicles with axle weights less than 3.6 tons including small and medium-sized trucks!

• Using the toe and camber mechanism, the tester accurately determines whether a sideslip level is acceptable during straight running of a vehicle.

• The box structure means the device can be easily installed.

In combination with a BS or ABS tester, this series streamlines measurements on 4WD vehicles.

• The rollers provide safe, quick vehicle inspections that require no cumbersome setup.

• The series covers a wide range of vehicle types with axle weights of up to 3.6 tons including medium-sized trucks, packers, and truck cranes.